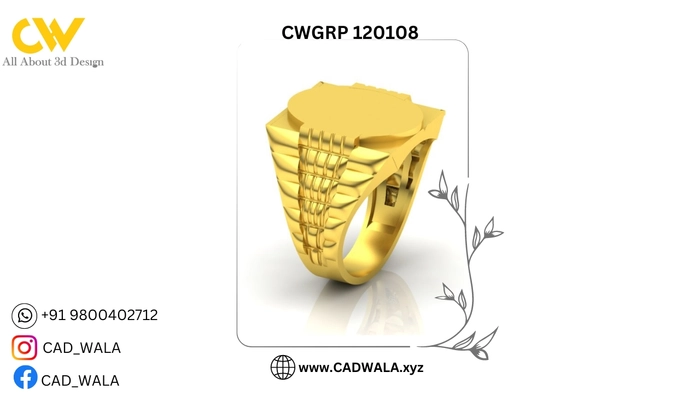

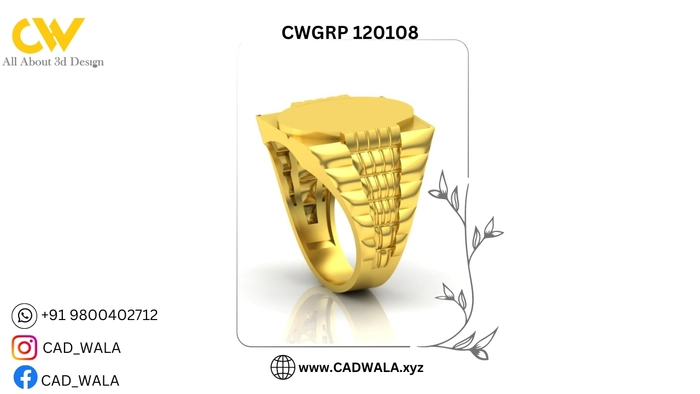

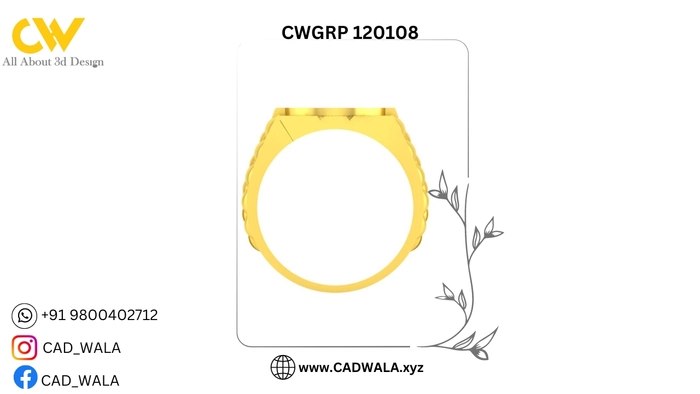

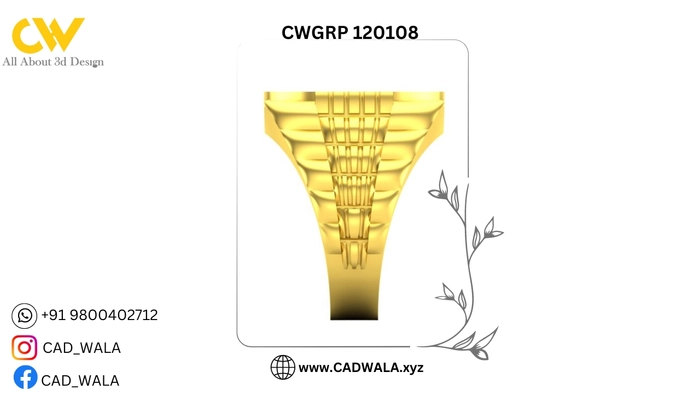

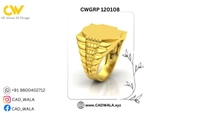

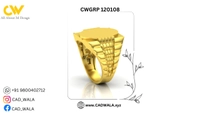

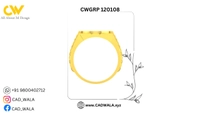

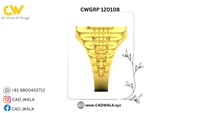

GENTS RING PLAIN (CWGRP 120108 )

Product details

Introducing the GENTS RING PLAIN (CWGRP 120108) - a timeless symbol of sophistication and style. Crafted with meticulous attention to detail, this exquisite ring is designed to captivate across generations. Made for the modern gentleman who demands excellence in every aspect of his life.

The simplicity of the plain band effortlessly enhances any ensemble, adding a touch of understated elegance to your look. Its versatile design makes it a perfect accessory for all occasions, whether it's a formal event or a casual outing. With its smooth and polished finish, this ring glows with a subtle radiance, sure to catch the eye of all who behold it.

Indulge in the luxury of this GENTS RING PLAIN, a testament to superior craftsmanship and timeless sophistication. Elevate your style and make a lasting impression with this must-have accessory, perfect for the discerning man who appreciates fine quality and refined aesthetics.

-

Downloading or creating a 3D file: You can find a wide range of 3D files available for download on various websites. Alternatively, you can create your own 3D files using 3D modeling software, such as Tinkercad, Blender, or Rhino.

-

Preparing the file: Before printing the 3D file, you will need to prepare it for 3D printing. This involves ensuring that the design is optimized for printing, meaning it is watertight and has the appropriate wall thickness for your chosen printing method.

-

Choosing a printing method: There are several different methods for 3D printing, and each has its own advantages and disadvantages. FDM printing is the most common method and is affordable and easy to use, but it may not be ideal for producing highly detailed jewelry. SLA printing uses a liquid resin that is cured with UV light to create very detailed prints, while SLS printing uses a laser to melt and fuse powder materials to create complex shapes.

-

Printing the design: Once the file is prepared and the printing method is chosen, you can begin printing the design. This can take anywhere from a few minutes to several hours, depending on the complexity of the design and the size of the jewelry piece.

-

Post-processing: Once the print is complete, you will need to do some post-processing to remove any support structures and smooth out any rough edges. Depending on the printing method used, this may involve sanding, polishing, or chemical treatments.

-

Assembly: Some jewelry pieces may require assembly after printing. This may involve using adhesives or fasteners to attach different parts together.

-

Final touches: Finally, you can add any finishing touches to the jewelry piece, such as adding clasps, polishing the surface, or adding gemstones or other embellishments.

Using 3D files for jewelry making is a great way to create unique and personalized pieces. It is an accessible and cost-effective way to produce high-quality designs and allows for a lot of flexibility in terms of design options. While it may require some technical knowledge and skill, it is a fun and rewarding process that can result in beautiful, one-of-a-kind jewelry.