3D jewelry design and manufacturing offer several benefits, but there are also some disadvantages that need to be considered. Here are some pros and cons of 3D jewelry:

PROS

-

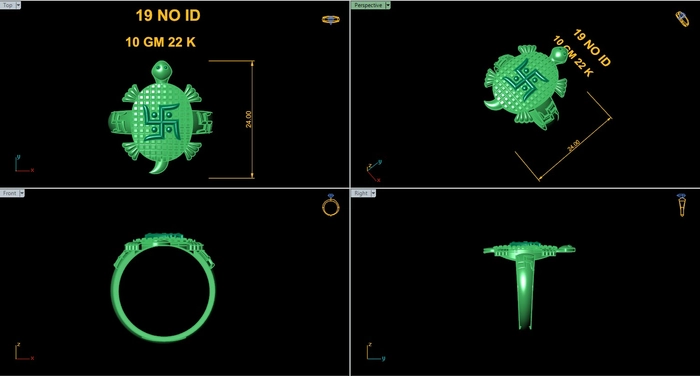

Customization: One of the most significant advantages of 3D jewelry is the ability to create highly customized and unique pieces. With 3D design software, jewelry designers can create complex shapes and patterns that would be difficult or impossible to achieve with traditional manufacturing methods. Additionally, 3D printing allows for personalized engravings and messages on the jewelry piece.

-

Faster Production: 3D printing can significantly reduce the time required to produce a jewelry piece, especially for complex designs. This means that designers can bring their ideas to market more quickly, which can be a significant advantage in the highly competitive jewelry industry.

-

Improved Quality: 3D printing technology offers high precision and accuracy, resulting in better quality jewelry pieces with intricate details. Additionally, 3D printing can produce consistent results, reducing the risk of defects or variations in the final product.

-

Reduced Costs: 3D printing can be more cost-effective than traditional manufacturing methods, especially for small batch production. The technology eliminates the need for expensive molds or tooling, reducing upfront costs. Additionally, 3D printing can minimize material waste, further reducing costs.

-

Accessibility: 3D printing has made jewelry design and production more accessible to small businesses and individuals who may not have access to traditional manufacturing equipment. With the availability of low-cost desktop 3D printers, anyone can create jewelry designs and bring them to life.

CONS

-

Limited Material Options: While 3D printing technology has advanced significantly in recent years, the types of materials available for 3D printing can be limited. This can restrict the types of jewelry pieces that can be created, especially for pieces that require specific material properties, such as high durability or flexibility.

-

Complexity: 3D jewelry design and production can be complex, requiring specialized knowledge and expertise that may not be readily available. This can result in a steep learning curve for designers and jewelers who are new to 3D printing technology.

-

Post-Processing Requirements: 3D printed jewelry may require additional post-processing to achieve the desired finish. This can include sanding, polishing, or plating, which can be time-consuming and expensive.

-

Cost of Equipment: While 3D printing equipment has become more accessible and affordable in recent years, it still requires a significant investment. Additionally, maintaining and repairing 3D printers can be costly, especially for larger industrial-grade machines.

-

Environmental Concerns: The use of 3D printing technology in jewelry production can have environmental consequences due to the production of plastic waste and the energy consumption required to power the printers. However, many 3D printing materials are recyclable, and some jewelry designers are experimenting with more sustainable materials, such as recycled metals and bioplastics.

In conclusion, 3D jewelry design and production offer several advantages, including customization, improved quality, and faster production times. However, there are also some drawbacks to consider, such as limited material options, complexity, post-processing requirements, equipment costs, and environmental concerns. By carefully weighing these pros and cons, businesses can determine if 3D jewelry is the right choice for them.